Proudly Made in the USA

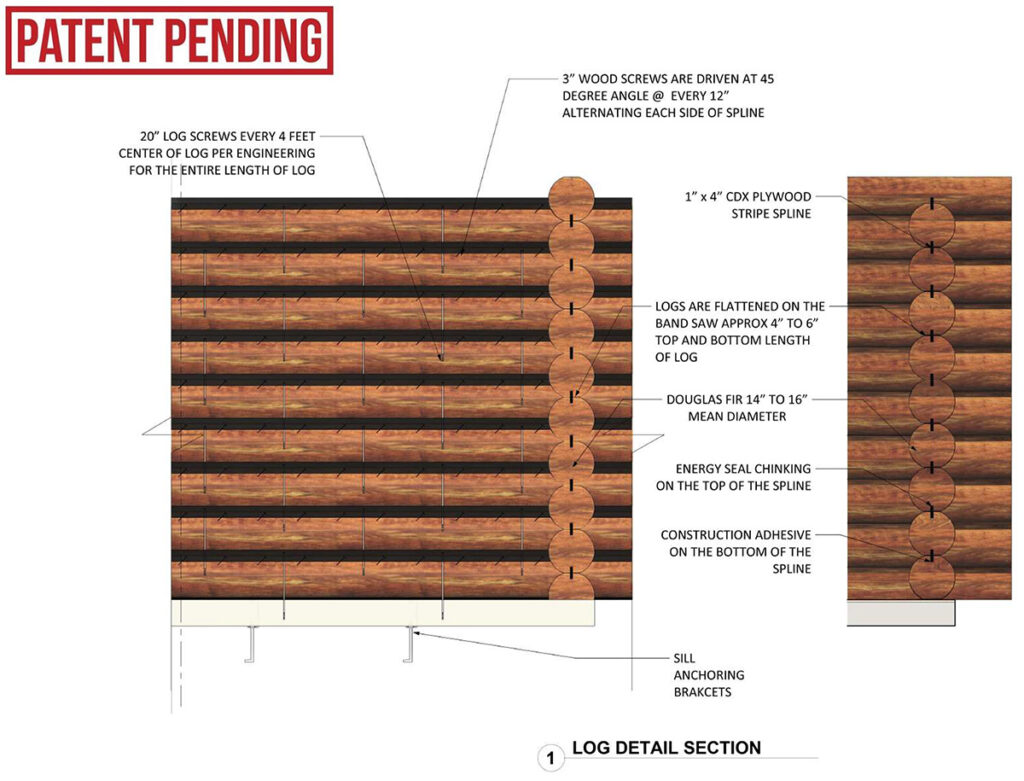

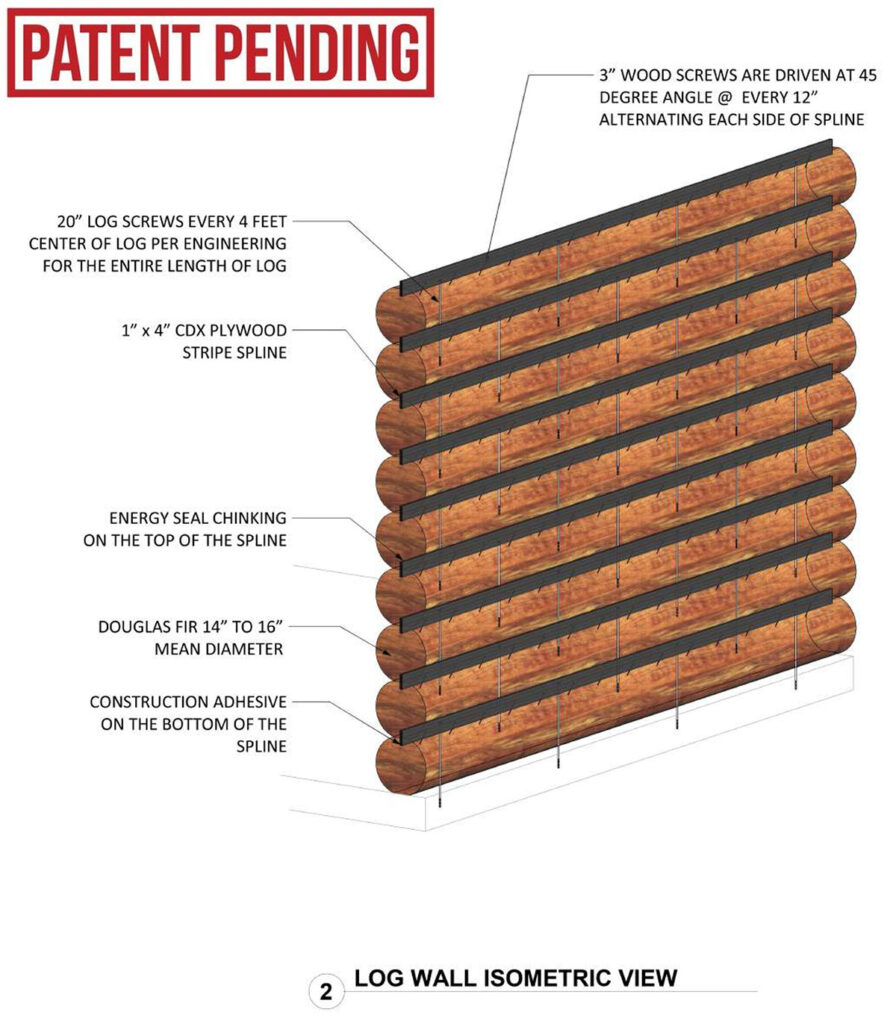

The present invention is a method for constructing a log wall that significantly improves structural integrity and weatherproofing compared to conventional log joinery. The system involves preparing logs by flattening two opposing sides and cutting a continuous, uniform groove along the length of each flattened face at the center of log. A dimensioned 1 x 4 CDX plywood spline is then used to join the logs.

Half the width of the spline being inserted into the groove of a log course, leaving the other half exposed. A non-expanding adhesive is applied to the groove and the spline is coated installed leaving half of it out for the next course. A foam gasket is placed against the spline and coated on each side with a liberal ½” bead of a chinking product before each log is joined. As the next log course is placed, it is aligned with the exposed portion of the spline, with the adhesive filling any voids, and then secured with fasteners.

Further, the spline is secured with 3” long Torx-Head wood screws, 12” apart, alternating each side of spline for the length of log to provide further stability. This system creates a uniform, continuous, and durable connection that prevents air and water infiltration while allowing for the natural expansion and contraction of the logs. It offers improved thermal efficiency, enhanced structural stability, and reduced long-term maintenance.

Patent Pending

Superior Air Sealing

Continuous Barrier: Conventional log joinery, particularly traditional chinking or simple overlapping joints, often relies on manual, intermittent sealing. This leaves opportunities for air and moisture to infiltrate between log courses. The Air Defender design creates a continuous, uninterrupted barrier with the full-length spline and adhesive, completely sealing and eliminating drafts.

Accommodates natural movement: All the logs expand and contract with changes in temperature and humidity. With traditional butt and pass or saddle-notch corners, this movement can cause gaps to open up over time, requiring frequent resealing. The combination of a spline and flexible adhesive allows for this natural movement without compromising g the seal, creating a durable and long-lasing connection.

Patent Pending

Enhanced Structural Integrity

Consistent strength: Conventional log joinery, like simple butt joints, can be a weak point in the wall system. While splines are used in many modern log homes for sealing butt joints, this system extends the use of a spline for the entire length of the log. This makes the wall more consistently strong and stable throughout.

Uniform distribution of loads: The continuous spline and flattened log surfaces provide a consistently sized surface for logs to rest upon, ensuring that the weight of the structure is distributed uniformly along the entire wall. This prevents settling and shifting that can occur with traditional notched or rounded log walls, where a precise fit is more difficult to achieve and maintain.

Patent Pending

Reduced long-term maintenance

Less need for chinking: Traditional log walls with visible gaps often require significant, and sometimes messy, chinking or caulking. This sealant degrades over time and must be reapplied periodically. By contrast, the Air Defender design conceals the primary seal within the logs, reducing or eliminating the need for visible chinking and it associated upkeep.

Hidden protection: The spline system places the core of the airtight and watertight seal inside the wall, where it is less exposed to the elements and physical damage. Any visible exterior caulking is a secondary seal, meaning the primary air barrier is better protected and requires far less maintenance.

This sophisticated 5-Point combination of spline/gasket system, multiple sealant points, and constant compression effectively prevents air and moisture infiltration, enhancing the home’s comfort and energy efficiency. It is a modern, high performance approach that maintains the solid log aesthetic while addressing traditional log home challenges.

Patent Pending